GibbsCAM Training Options

Whatever your level of GibbsCAM expertise, we’ve got training to give you the tools to program parts faster and more efficiently.

Training Class Request

Please fill out the form below to express your interest in training classes.

Choose from a variety of GibbsCAM training classes: Basic Mill, Basic Lathe, Advanced Mill, and Macros.

Each class is taught by an experienced instructor, ensuring that you are confident in your new skills.

Classes are held over 6 weeks, one day a week, for 4 hours, totaling 24 hours of training.

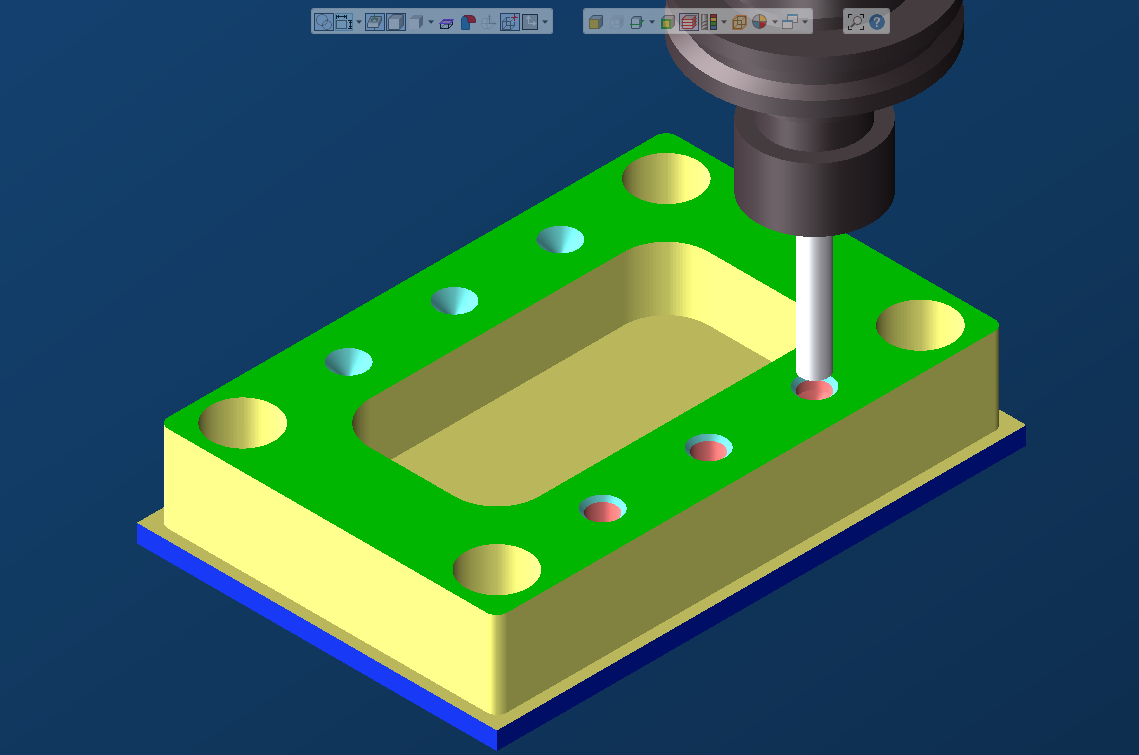

Basic Mill

Join our milling class to explore the fundamentals of GibbsCAM. The curriculum includes navigation of menus, tiles, and windows, wireframe geometry creation, and the development of both basic and custom tools. Students will also learn to create and edit toolpaths and work with solids in a 2.5D environment. This hands-on course is designed to enhance your milling skills and build a solid foundation in CAM programming.

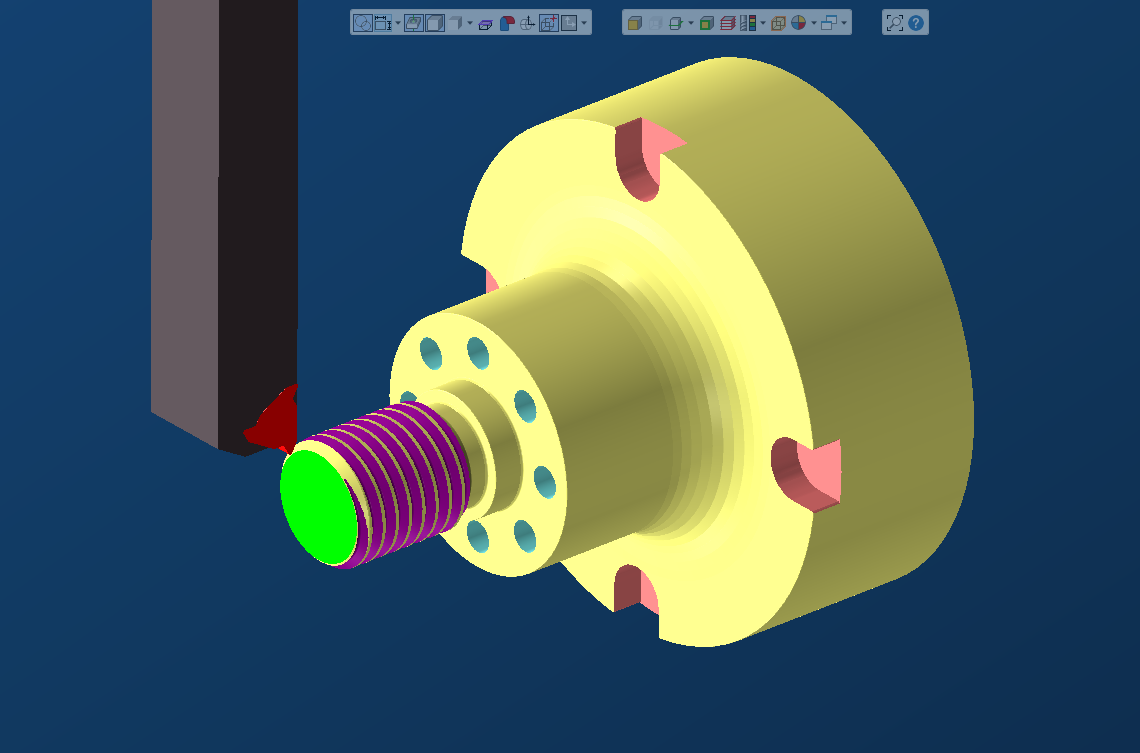

Basic Lathe

This course offers a comprehensive introduction to GibbsCAM, focusing on essential skills for turning operations. Participants will learn to navigate menus, tiles, and windows, create wireframe geometry, and develop basic and custom tools. Additionally, the course covers toolpath creation and editing, along with using solids in a 2.5D environment, equipping students with the practical knowledge to enhance their programming capabilities.

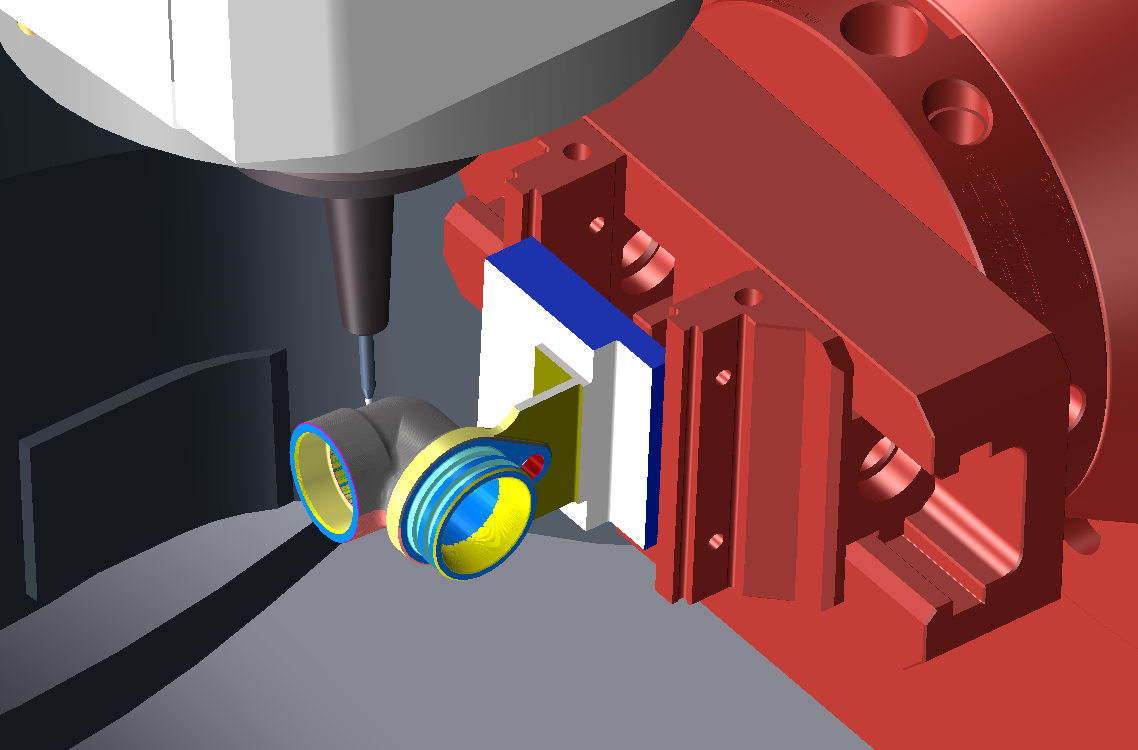

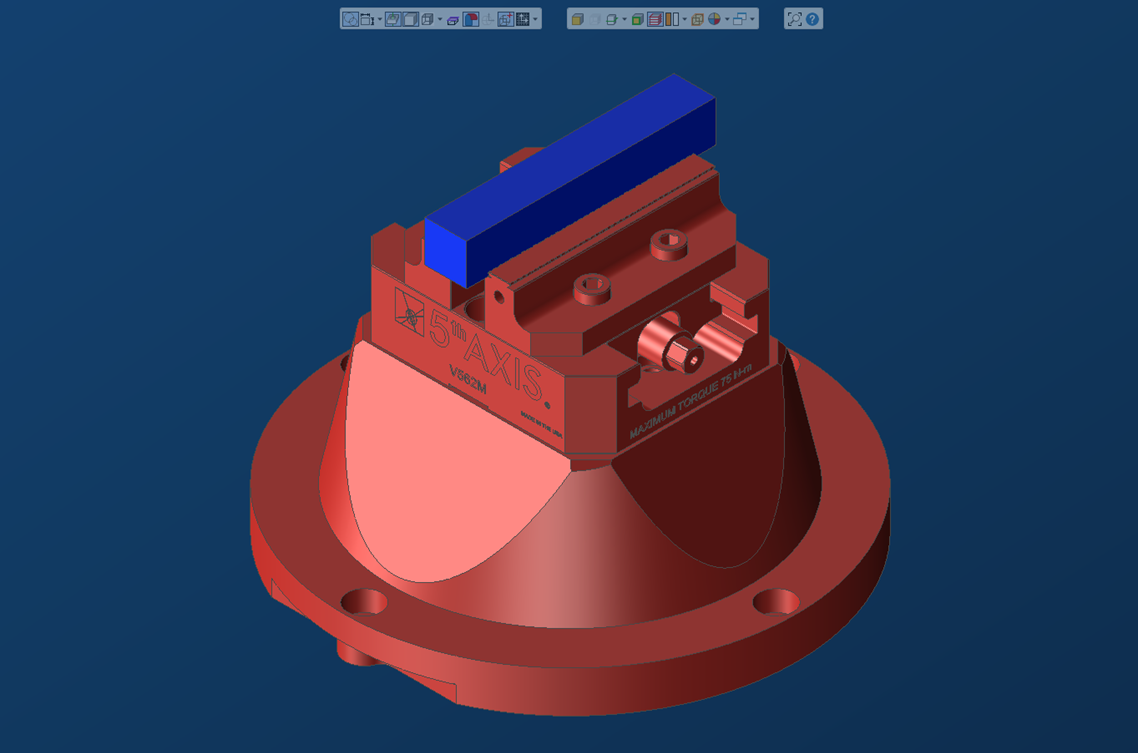

Advanced Mill

Elevate your milling expertise in our advanced GibbsCAM class, where you’ll delve into coordinate systems (CSs) essential for precision machining. This course covers the creation and modification of CSs, including how to move and rotate them for optimal use. You’ll gain practical insights into applying these concepts in both flat and rotary applications, enhancing your ability to tackle complex milling projects with confidence.

Macros

Enhance your machining efficiency in our GibbsCAM Macros class, where you’ll discover the power of automation in your workflow. You’ll learn how to open and create files, develop solid models, and associate processes with geometry. Additionally, you’ll explore using math functions within macros and designing custom tool holders that integrate tools with specific processes, streamlining your operations for greater efficiency.

Free GibbsCAM Tutorials

Whether you’re a new GibbsCAM user, or in need of a refresher, our two new tutorial series walk you through how to use GibbsCAM to program a mill part, beginning to end, from either a print or a solid.