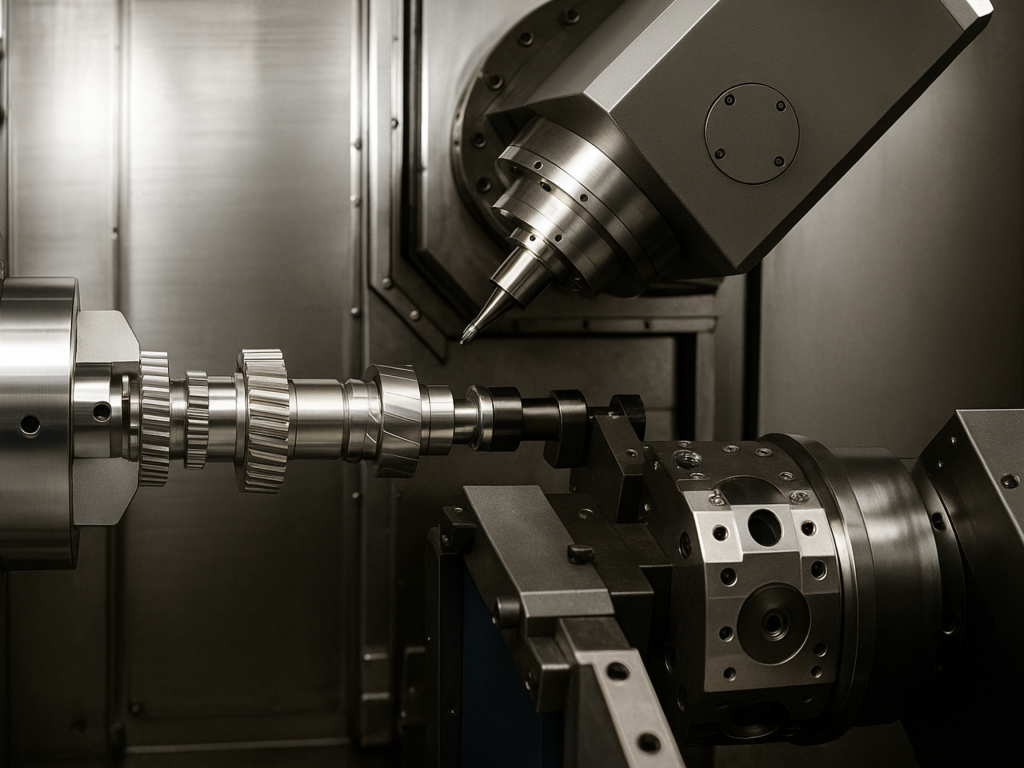

Precision CNC Programming

Plus the Support you Need

GibbsCAM turns complexity into confidence. Mill, Lathe, MTM, Swiss & Wire EDM — done right the first time!

Your CAM Advantage Starts Here

Program Faster. Machine Smarter. Grow Stronger.

30%

Faster Programming

85%

Measurable ROI in 90 days

GibbsCAM 2026 is Here

ONE PLATFORM. EVERY POSSIBILITY.

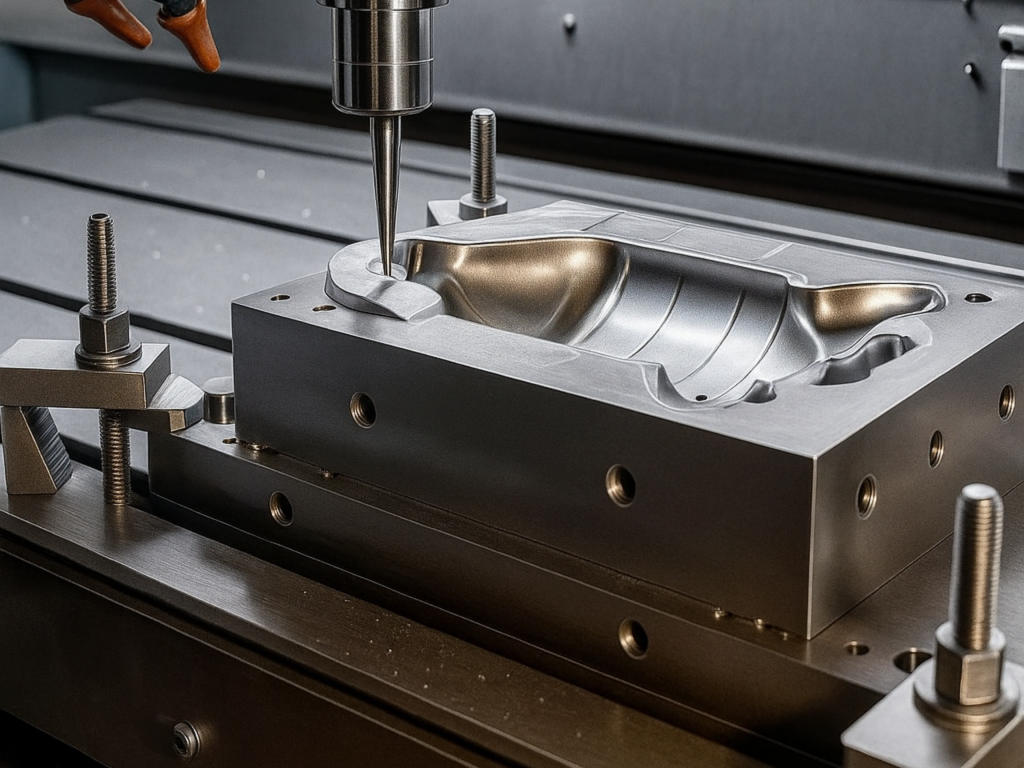

From Setup to Chip. Make It Count.

From software to simulation, post processors to on-demand support, we help you program smarter, train faster, and machine with confidence. Every solution we offer is built to boost productivity where it matters most: on your shop floor.

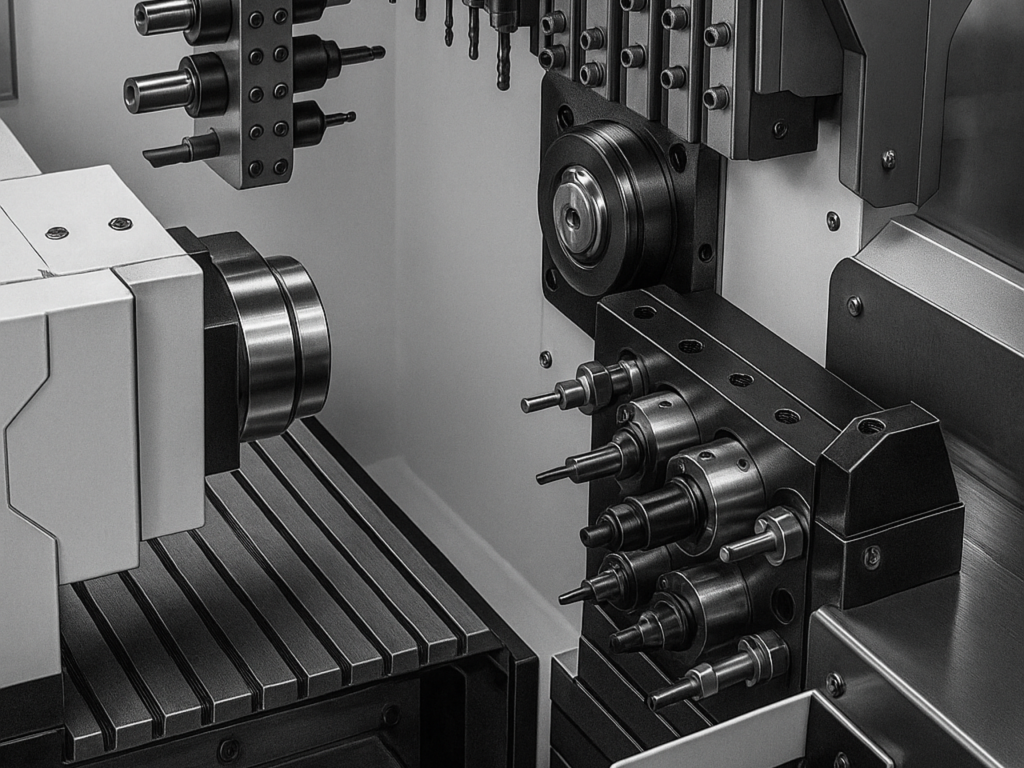

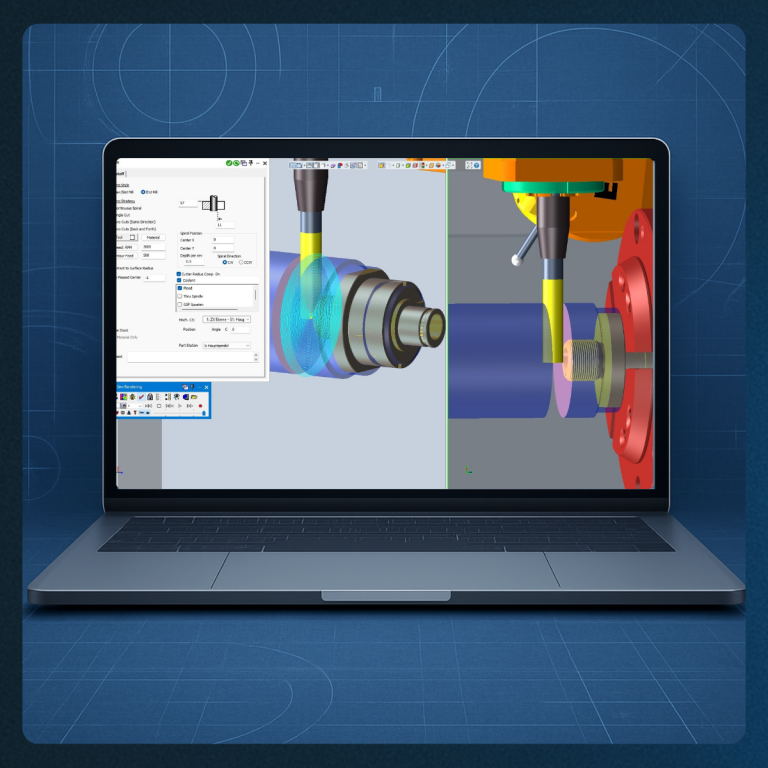

GibbsCAM Software

Explore options to simplify CNC programming & maximize machining speed and precision.

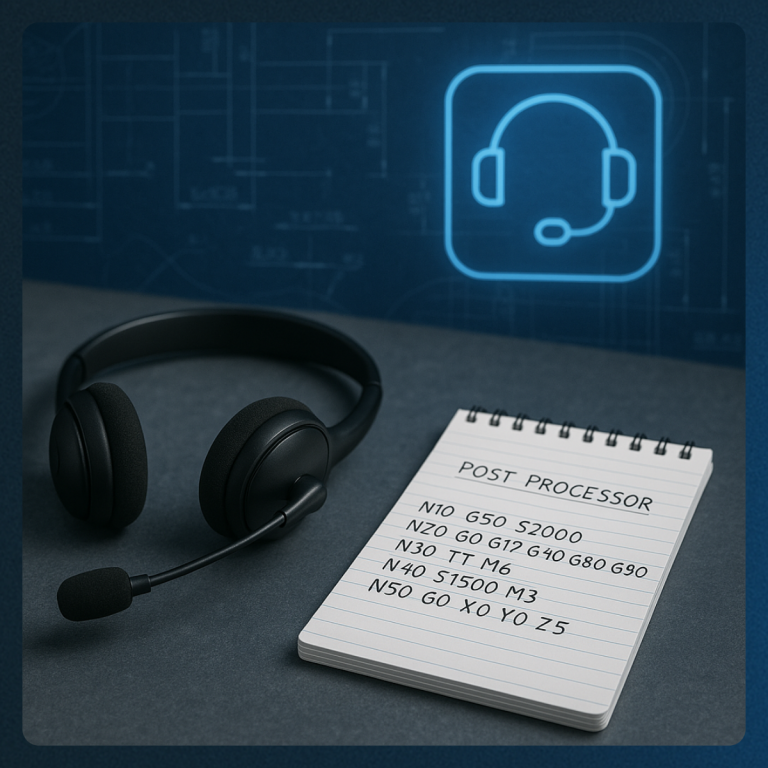

Support and Training

Unmatched training and expert support, so your team programs faster, solves problems quicker, and keeps machines running.

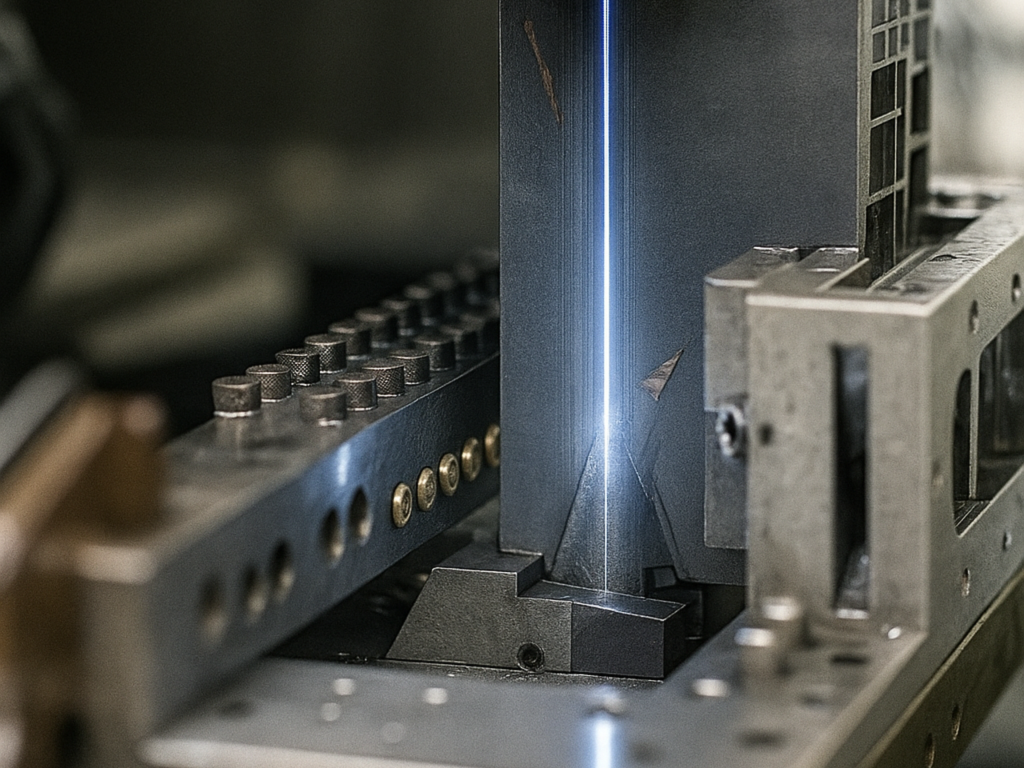

Custom Posts & Machine Sim

Get reliable posts and simulation models tailored for any machine, backed by GibbsCAM pros.

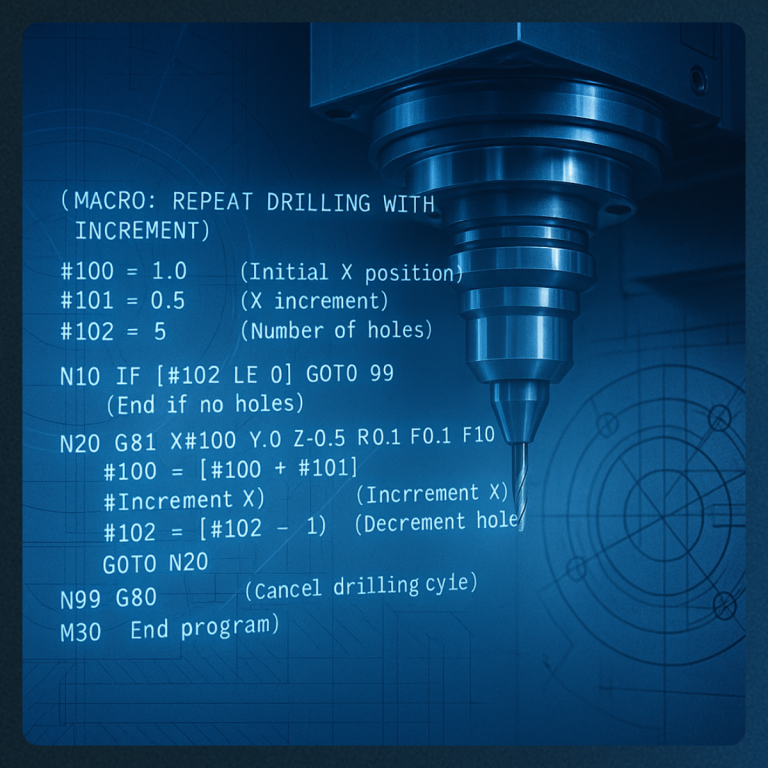

Macros & Automation

We develop custom macros to save time, reduce errors, streamline programming, and support shop-floor automation.

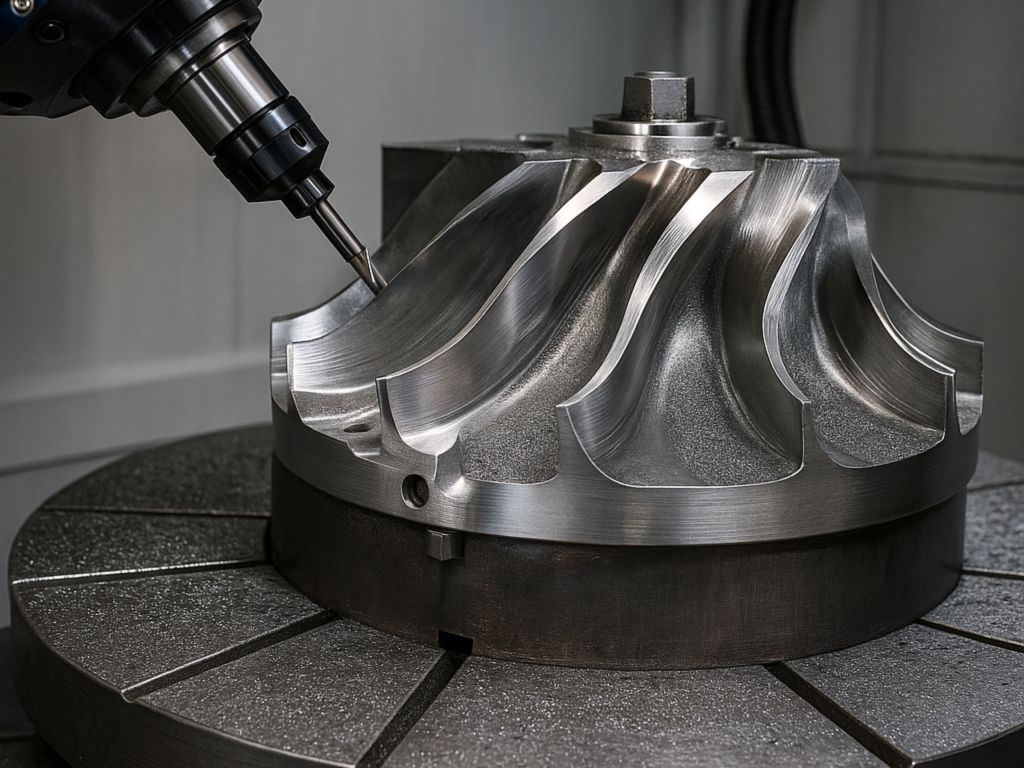

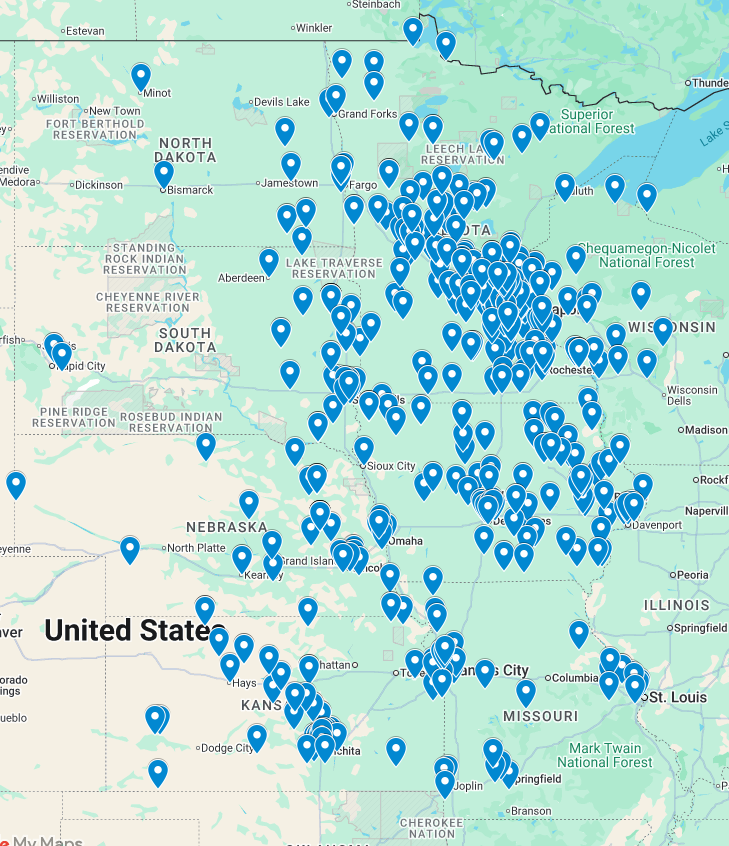

WHERE WE MAKE AN IMPACT

Whether it’s a one-machine garage shop or a multi-state production line, we work with shops throughout Minnesota, Iowa, North and South Dakota, Missouri, Nebraska, and Kansas to deliver practical, powerful CAM solutions.

CAM Solutions for Every Shop Type

YOUR CAM EXPERTS

CEO

Sales & Customer Success

Applications Engineer

Project Engineer

Applications Engineer

Maintenance Manager