What's New in GibbsCAM 2025

Powerfully Simple. Simply Powerful.

GibbsCAM 2025 incorporates cutting-edge turning technologies, equipping their clients with AI capabilities, and offering convenient access to extensive manufacturing and tooling expertise. The integration of Sandvik’s cutting-edge technology continues, starting with Sandvik Coromant PrimeTurning™, the implementation of Y-axis turning, and now Sandvik OptiThreading™. This leads to a significant improvement of efficiency and productivity, both in engineering as well as in production. GibbsCAM continued to work towards its goal of becoming the CAM solution of choice for Sandvik Coromant turning technologies.

Unlocking the Full Potential of Turning

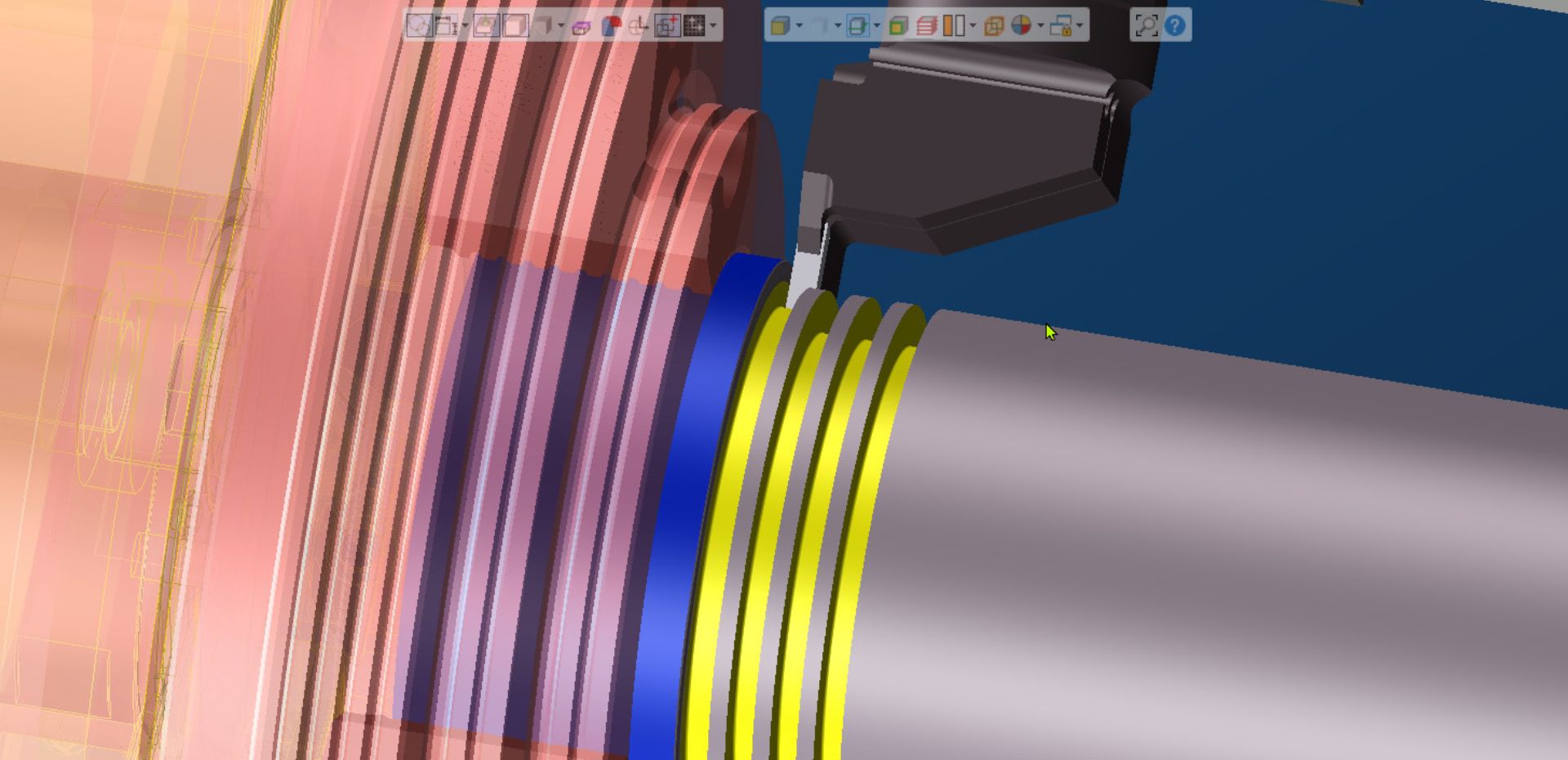

Y-Axis Turning

With the insert positioned in the Y-Z plane, Y-axis Turning effectively directs the primary cutting forces into the milling spindle, providing exceptional stability. This yields superior chip control, improved surface finish, and increased cutting speeds. Furthermore, the inclusion of a third axis for tool rotation allows for optimal positioning of the tool, enabling the cutting of intricate shapes with a single tool. This also enables a seamless “sweeping” motion for cutting complex shapes, preventing any blend marks and ensuring precise control of the insert wiper effect.

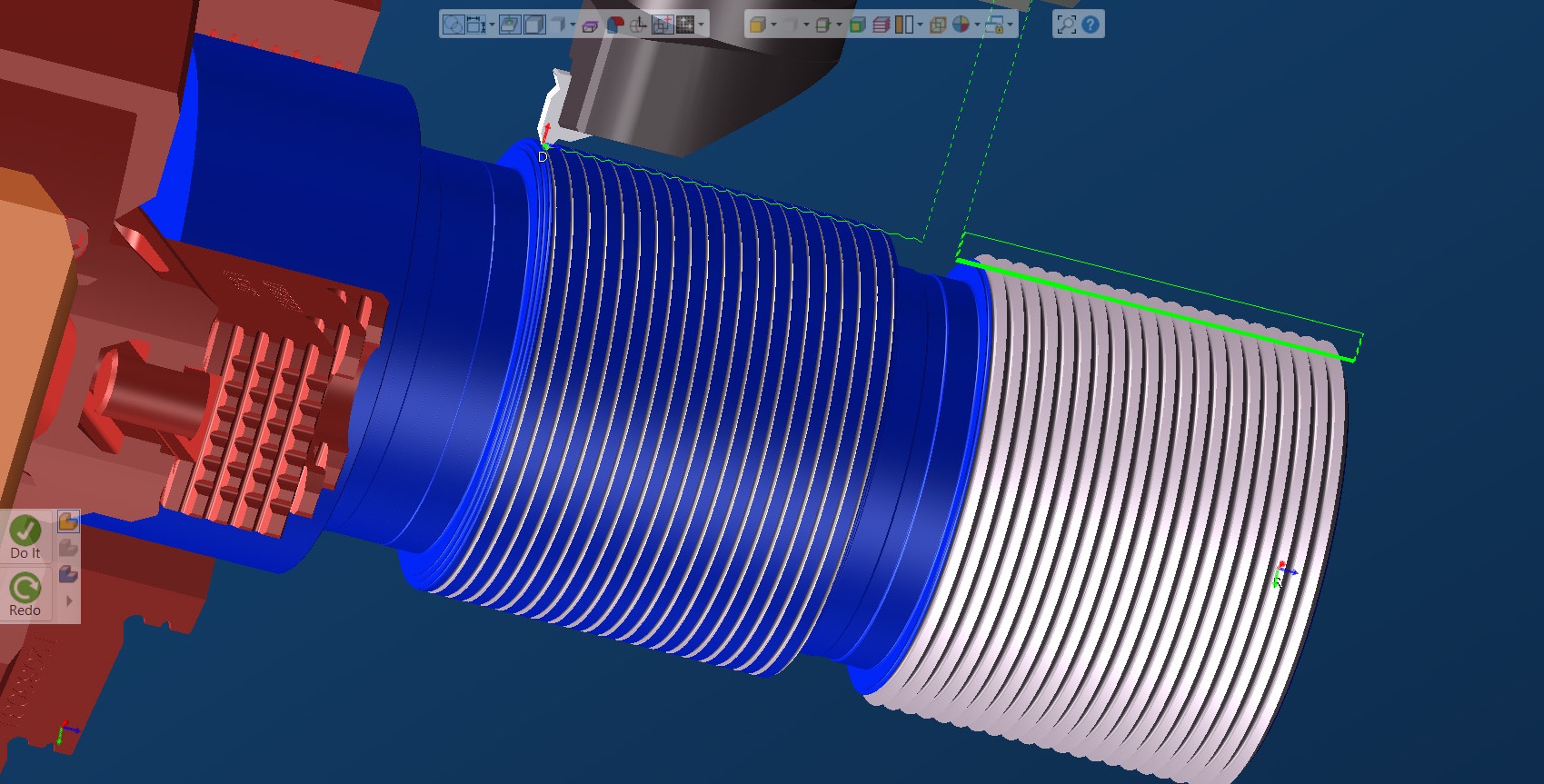

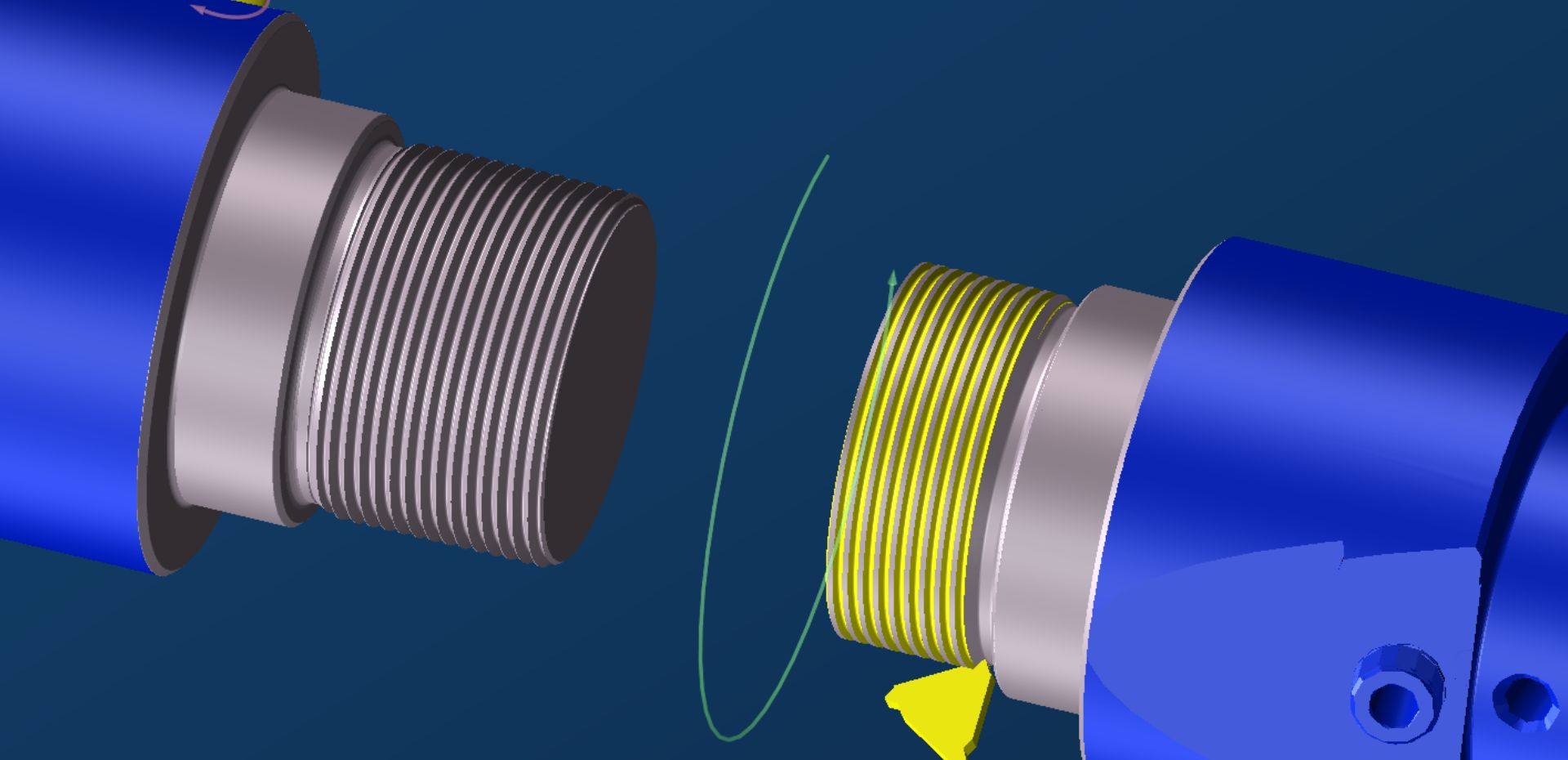

OptiThreading

GibbsCAM’s new turning strategy for OptiThreading™ enables controlled chip breaking to eliminate long stringy chips that can damage a component’s surface and interfere with the cutting zone. It is just as suitable for simple threads as it is for cutting complex thread profiles in high-strength alloys or exotic materials. Improved chip control results in improved quality, faster cutting speeds, and less manual work by reducing the need to manually clear long chips during the machine run cycle.

Rib Cut Plunge

This special turning strategy for roughing reduces tool deflection, improves tool life, and guarantees excellent chip control. Within a preliminary operation the tool repeatedly plunges into the part at full engagement to create a series of cuts with each cut more than a tool-width away from the previous one. The following pass cuts the remaining ribs at a 30-50% increase in feed.

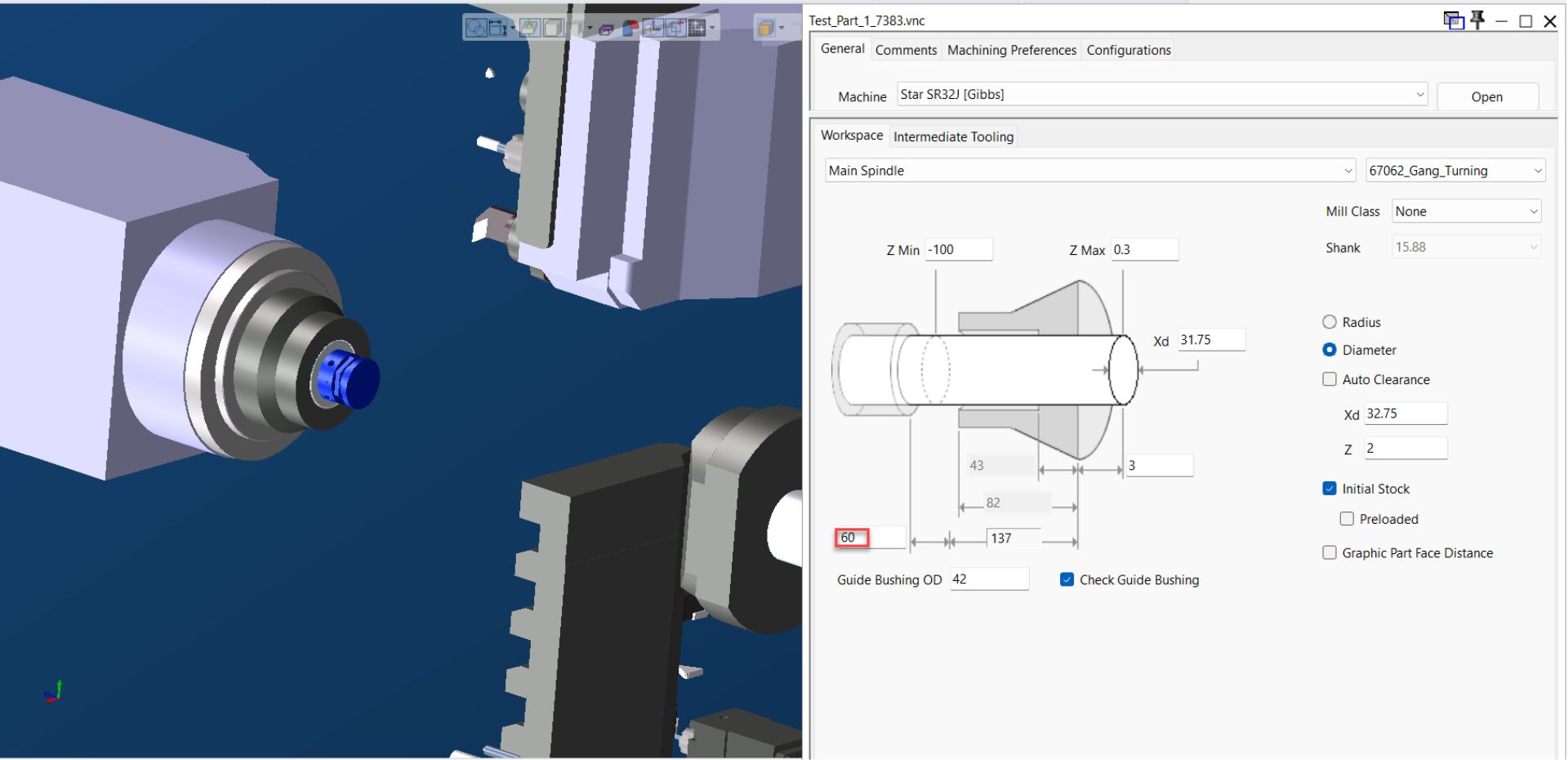

Swiss-type machining

As the leading CAM solution for Swiss-type machines GibbsCAM 2025 introduces a new option for the headstock origin. This allows the NC programmer to define a value for the distance between the front of the guide bushing and the headstock’s 0 position. With that, the correct positioning of simulation bodies on the headstock axis becomes easier. It provides a more intuitive interface in the dynamic coordinate definitions for Swiss-style machines.

The new option for headstock origin makes it easier to position simulation bodies on the headstock axis.

Comprehensive Performance Boost

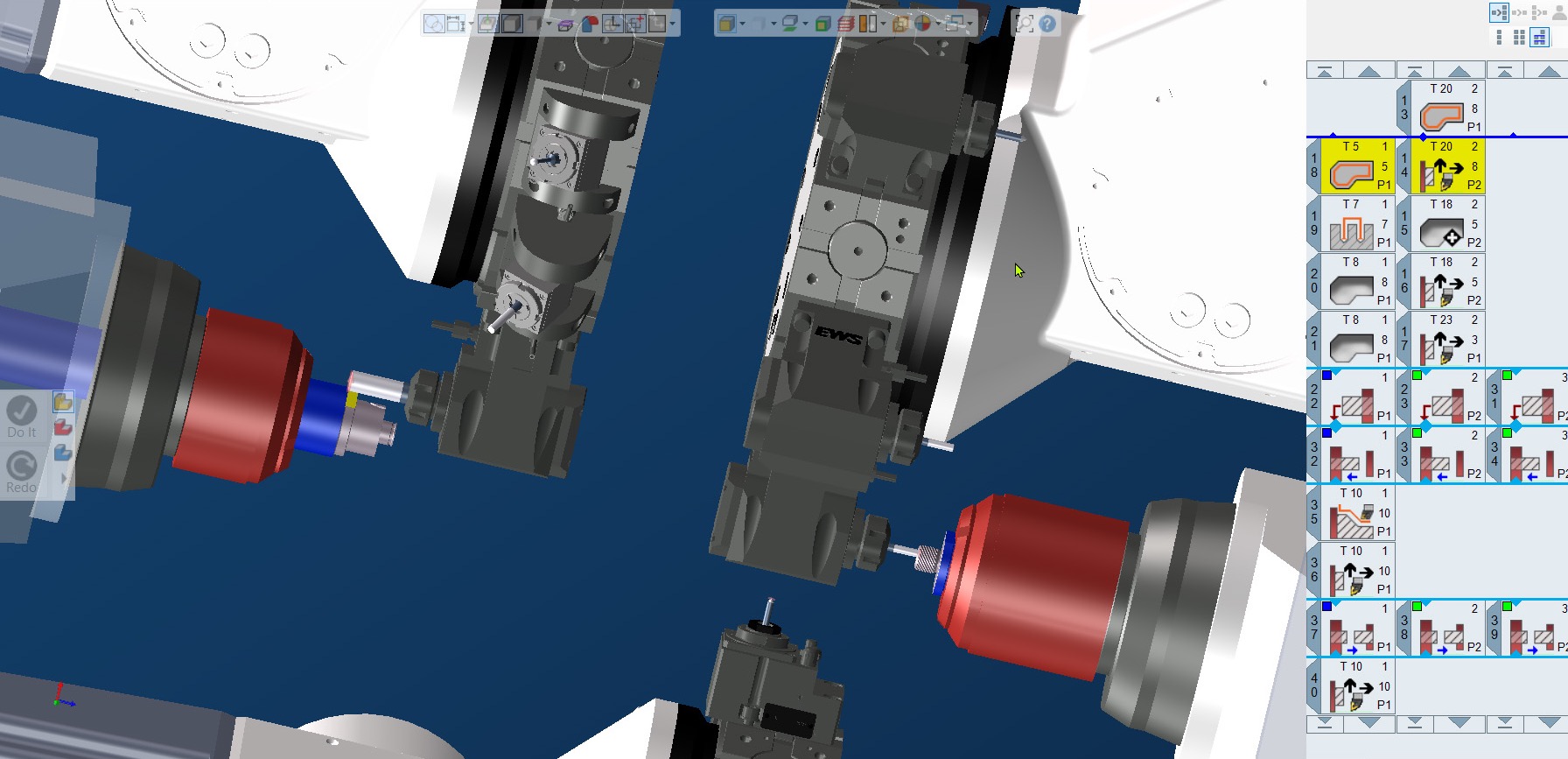

Visualization of multi flow operations

Within its powerful Multi Task Machining solution, GibbsCAM supports the most complex MTM and Swiss machines with an unlimited number of axes in any axis orientation. To always give the user the best view on the defined multi flow operations, GibbsCAM 2025 provides new additional Operation Tile Modes to display multiple flows independent of the MTM Sync Manager. Users can choose to Show All Flows for a comprehensive view, Show Each Flow for focused management, or use Sync Flow Mode to coordinate displays across operations, improving organization and control of multi flow processes.

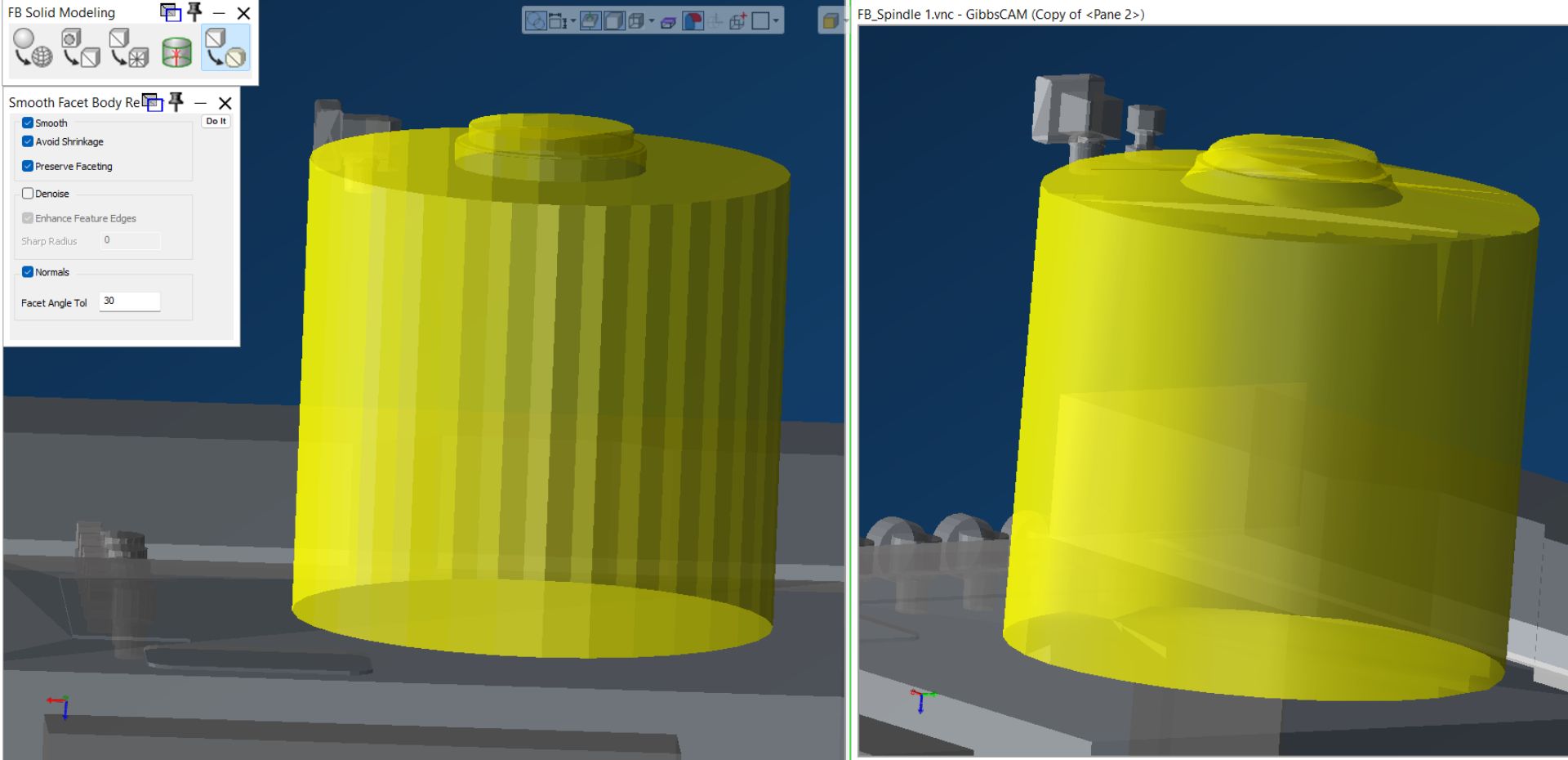

Facet Body Modeling

Facet Body can play an essential role in modern CAM workflows, bridging potential gaps between design and manufacturing, enabling precise and optimized production processes. GibbsCAM 2025 provide users with powerful tools for manipulating facet body models without the need for external CAD software.

The new Facet Body Modeling palette supports a wide range of specific editing functions, including Tesselate, Simplify, Re-facet, Heal and Smoothing of facet bodies. Many existing Solid Modeling functions now support Booleans, Slice, Separate, Offset/Shell, History, and more. With this new functionality, GibbsCAM users can now easily work with Facet Body models such as parts, machine components, fixtures, and In-process Stock Models directly within GibbsCAM.

Powerful Tool Management

Simulation Enhancements

New Simulator enhancements increase user control for greater accuracy, such as the new stop option to pause the simulation before each operation. A new scrolling bar in the Sync Manager tracks simulation progress, providing real-time feedback for MTM machining operations. The innovative “Rotary Hint” option displays the spindle direction for both Turning and Milling. To enhance safety, collision detection and alerts are now activated by default.

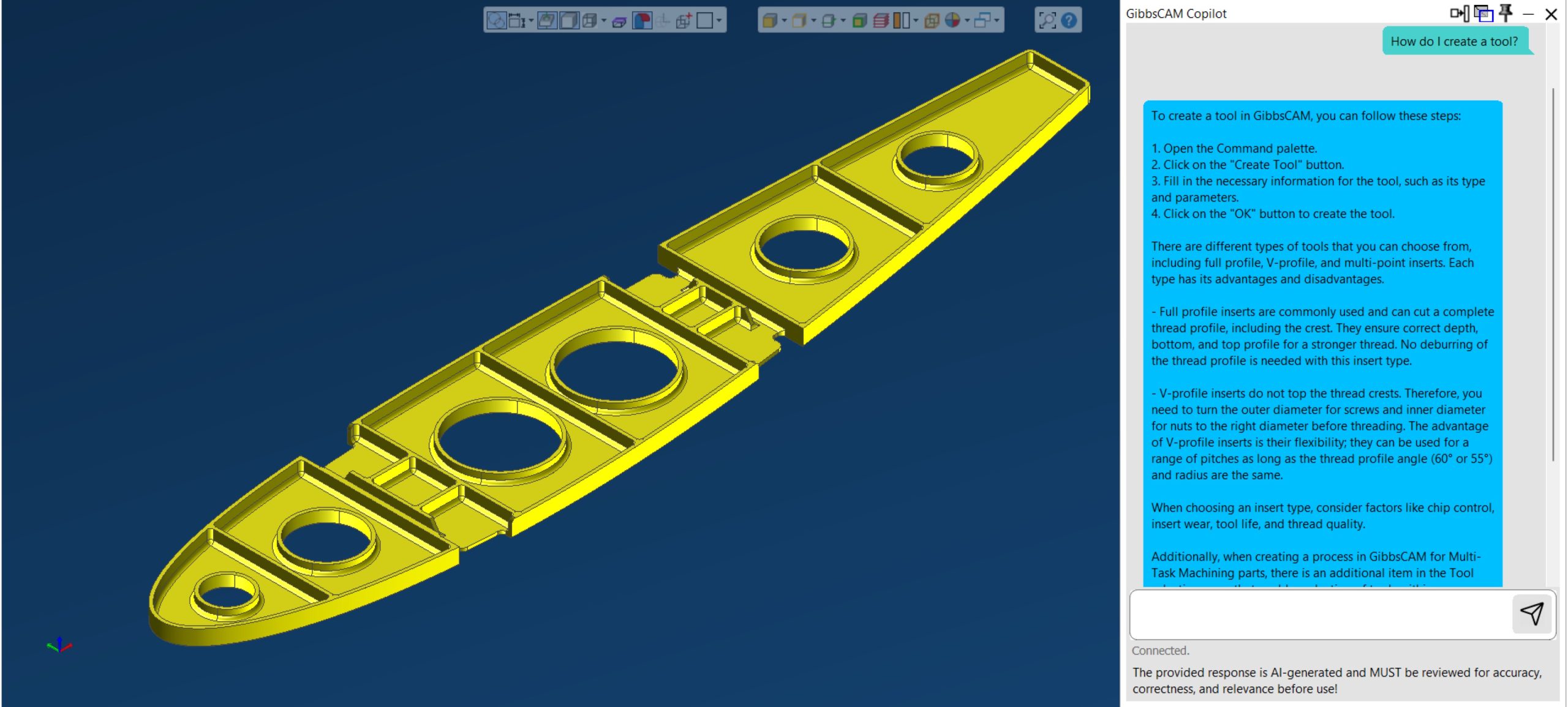

Fast and Effective AI Support

GibbsCAM Copilot

GibbsCAM Copilot provides rapid user support at any time without the need to hunt through documentation or reach out for support. Copilot makes getting the information you need quick and easy, resulting in faster programming.

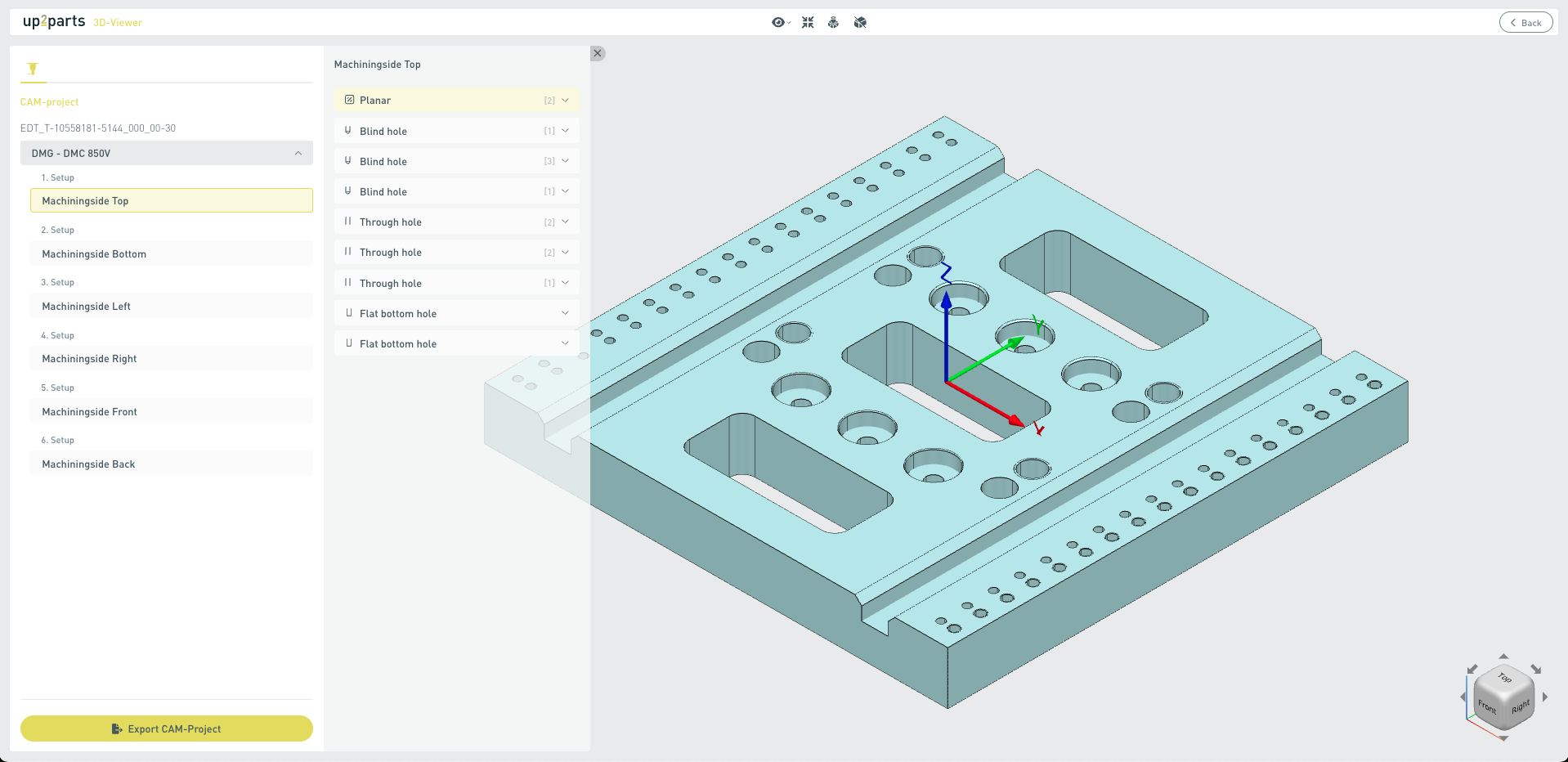

up2parts AI-driven Part Programming

GibbsCAM 2025 offers integration with up2parts to accelerate CNC programming by up to 70%! up2parts uses 3D models to create recommended part processing, including tooling, work holding, and toolpath. Based on the up2parts’ recommendations, GibbsCAM automatically creates the tools and operations based on provided AI-driven manufacturing guidelines.