Solutions

One Solution. Every Workflow. Zero Compromises.

Say goodbye to slowdowns, toolpath trouble, and idle machines. GibbsCAM gives you the tools, posts, and support to keep parts moving, faster, smarter, and with less stress.

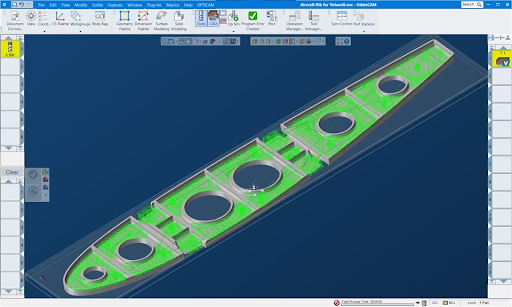

Milling

Go from CAD to cut faster with smart geometry tools, customizable strategies, and VoluMill’s ultra-efficient roughing. GibbsCAM simplifies toolpath creation while giving you full control over speed, stepdowns, and material engagement.

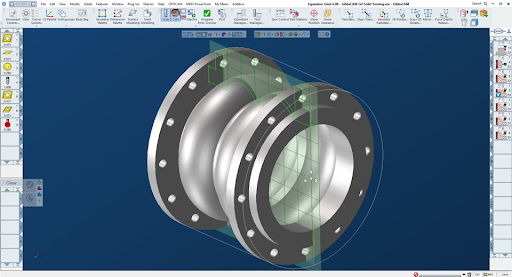

Turning

Handle complex turning operations with confidence. GibbsCAM makes it easy to program live tooling, grooving, part cutoffs, and Y-axis moves with clean, editable output your machine actually understands and your team can trust.

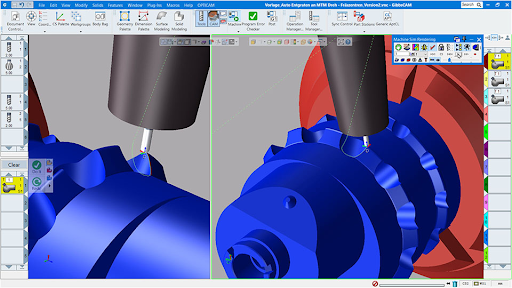

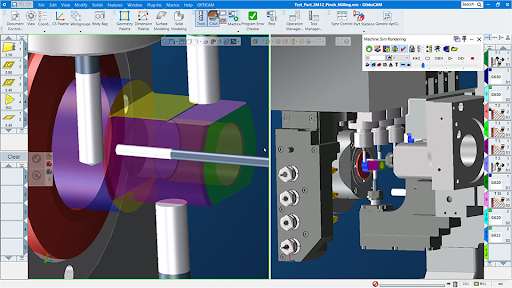

Multi-Axis

Multi-axis milling enables 3 to 5-axis simultaneous machining for complex geometries, smoother toolpaths, and efficient deburring. This module is ideal for tight-tolerance parts and reducing setups in one streamlined process.

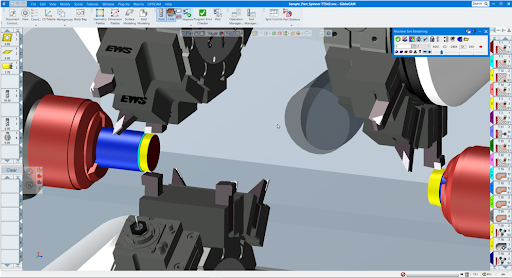

MTM

Multi-tasking doesn’t have to mean multi-frustration. GibbsCAM’s MTM module supports syncs, subspindles, turrets, B-axis heads, and more from one interface, with the logic baked into the post.

Swiss

GibbsCAM Swiss is built specifically for sliding head machines. Full tool sync control, guide bushing handling, part transfer logic, and simulation help you prove it out before you press cycle start.

Wire EDM

EDM without edits. Get full control of start points, skim cuts, tags, and tapers with verified post output that matches your machine’s real behavior and eliminates time-wasting trial and error.

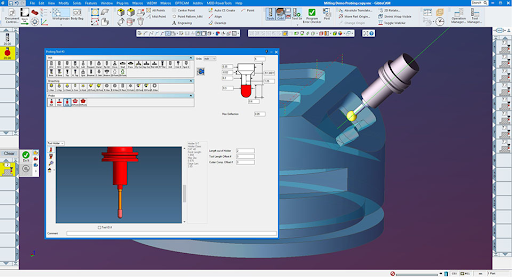

Probing

We integrate probing logic directly into your post to match your control. Great for setup, mid-cycle checks, and in-process inspection without adding complexity to the programming.

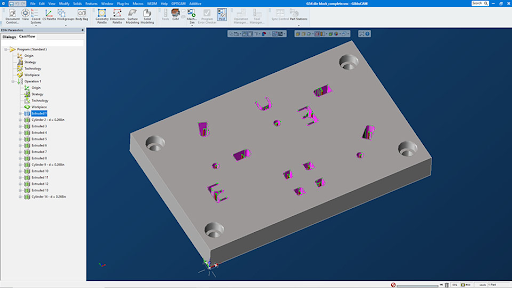

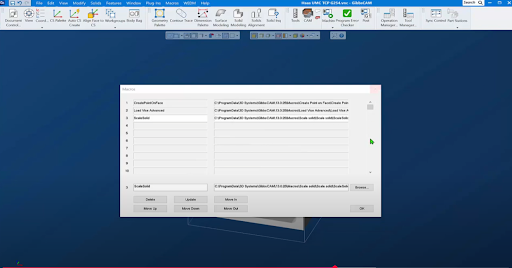

Macros & Automation

Automate toolpath creation, reduce errors, and scale repeat programming. High-mix shops use macros to save hours and train new programmers faster.

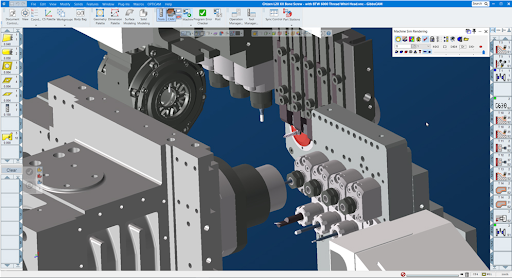

Machine Simulation

Cut crashes before they happen. GibbsCAM’s simulation reflects the actual motion of your machine, your posts, and your program, because guesswork is expensive.

Smarter Together: Tech That Plays Nice

VERICUT

For shops where mistakes aren’t an option, VERICUT provides industry-leading NC-level verification. It simulates the exact machine code, not just CAM toolpaths, so aerospace, defense, and medical manufacturers can trust every cut. We help configure and integrate VERICUT alongside GibbsCAM to ensure your simulation reflects real-world output all the way to the machine.

up2parts

AutoCAM by up2parts transforms your programming workflow by automatically analyzing 3D CAD models, including tolerance data, and generating smart, ready-to-use CAM strategy suggestions. Within minutes, it recommends optimal clampings, tools, operations, and processing steps, helping your team save time, reduce errors, and focus on what matters most: efficient, high-quality machining.

Machine Tool Partners

We work directly with top machine builders like Okuma, Tsugami, Mazak, Haas, and DMG Mori to ensure your post processor is dialed in to match your control and machine behavior. From spindle orientation to custom M-codes, everything is aligned so your programs run exactly how you expect with no surprises.