Case Study: Natoma Manufacturing

Fast Track to 5-Axis: How Natoma Scaled Production Without a Hitch

Results at a Glance

- Integrated two 5-axis machines with zero post or simulation issues.

- Onboarded new equipment into production faster than ever.

- Expanded production capacity to support future growth.

Natoma Manufacturing: Flawless 5-Axis Integration Without the Downtime

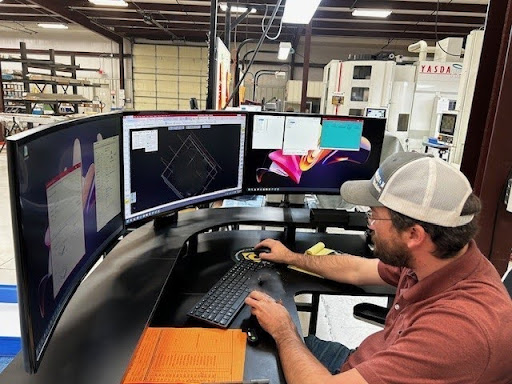

Natoma Manufacturing, based in Norton, Kansas, is a CNC contract manufacturer with a reputation for precision and reliability. Their skilled engineering team handles every stage in-house including quoting, CAD, CAM, and equipment implementation, so when it came time to integrate two new 5-axis machining centers, the stakes were high. Downtime, post processor errors, or workflow disruptions weren’t an option.

Already a GibbsCAM shop, Natoma turned to Midwest CAM Solutions for post development, simulation setup, and real-time technical support. The result was a seamless rollout from start to finish. Posts were built, tested, and fine-tuned quickly. Simulation was dialed in. Every adjustment happened in real time, so the machines could start producing without delay.

With both 5-axis machines fully online, Natoma immediately ramped up production capacity without introducing bottlenecks. The smooth integration not only boosted output but also strengthened their confidence in tackling future growth. With Midwest CAM Solutions in their corner, they have the tools, expertise, and trusted support to move fast, stay accurate, and keep delivering for their customers.

Under Pressure to Perform

Natoma’s in-house engineering team needed a flawless integration for two new 5-axis machines, with zero tolerance for downtime.

Choosing the Right Partner

Midwest CAM offered the expertise, consistency, and collaborative service Natoma valued most.

A Flawless Integration

Post development, simulation, and setup were completed without delays, with adjustments made on the fly.

Capacity, Confidence, and Growth

The smooth rollout increased capacity, eliminated bottlenecks, and gave Natoma confidence for future expansions.

Final Results

With zero post or simulation issues during the rollout of two new 5-axis machines, Natoma Manufacturing was able to integrate equipment into production faster, increase capacity, and position the team for future growth with full confidence in their CAM environment.

“Being able to implement new machines with no issues and keep production moving is a big deal. With GibbsCAM and Midwest CAM, we didn’t just avoid delays…we gained capacity and confidence.” – David Schlegel, Engineering Manager