Case Study: ICA Corporation

Powered by VoluMill, Backed by Support: ICA’s Formula for CNC Growth

Results at a Glance

- Shorter cycle times and cost savings using VoluMill.

- Expanded programming capability to 5-axis machining.

- Improved turnaround with fast, responsive support and personalized training.

ICA Corporation: Building on Experience, Expanding with Confidence

Founded in 1970, ICA Corporation has spent decades honing its expertise in metal fabrication, welding, and CNC machining. With 90 employees and a culture shaped by long-term commitment, (many founders still work in the shop) ICA blends craftsmanship with modern manufacturing.

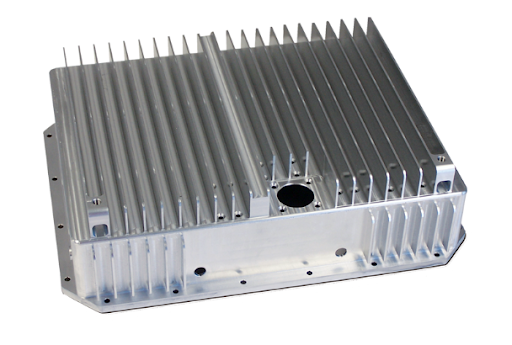

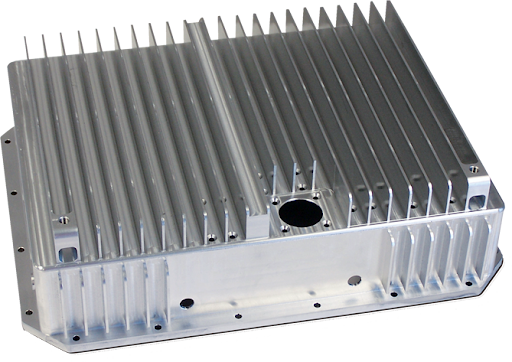

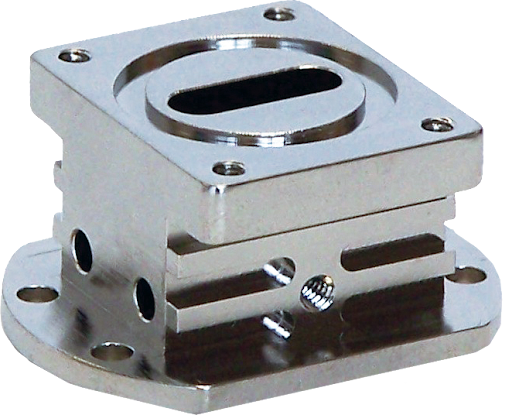

As customer demands grew more complex, ICA turned to a familiar partner: Midwest CAM Solutions. CNC programmers Shane and Matt led the charge, working with Midwest CAM to expand their capabilities with GibbsCAM. The shift unlocked 5-axis machining, slashed cycle times with VoluMill, and gave the team targeted training that made high-value projects feel within reach.

This wasn’t just about software, it was about building a stronger, more agile shop. Midwest CAM became an extension of ICA’s team, providing quick answers, hands-on help, and guidance that kept production moving. Today, ICA confidently tackles jobs they once might have declined, knowing they have the tools, skills, and support to deliver precision work faster than ever.

Built on Tradition, Powered by Precision

ICA’s roots in sheet metal and welding give them a strong foundation for taking on advanced CNC machining challenges.

A Long-Term Partnership Built on Trust

Decades of collaboration with Midwest CAM mean ICA always has a responsive, knowledgeable team in their corner.

Training. Tools. Teamwork.

Targeted training, feature unlocks, and on-demand support have helped ICA push their capabilities further.

Pushing Limits with Confidence

From 5-axis machining to VoluMill cycle time gains, ICA now approaches complex jobs with skill, speed, and certainty.

Final Results

With expanded 5-axis capabilities, reduced cycle times through VoluMill, and a team strengthened by ongoing training, ICA Corporation has positioned itself to take on more complex work, improve efficiency, and continue growing with confidence.

“GibbsCAM has helped us move into more advanced machining, and the support from Midwest CAM has been outstanding. Whether it’s training, troubleshooting, or new features, they’ve always been there to help us keep improving.” – Jeff Fishbaugher,