Case Study: Gauthier Industries

Model Shop, Modern Tools: How Gauthier Leveled Up with GibbsCAM + Midwest CAM

Results at a Glance

- Enabled 3D surfacing and solid modeling for reverse engineering.

- Resolved critical programming issues in real time with expert support.

- Accelerated toolpath iteration and testing directly at the machine.

Gauthier Industries: From Bottleneck to Breakthrough

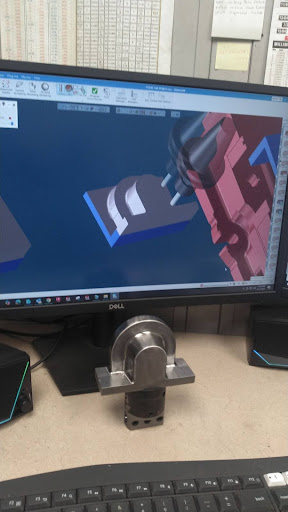

Gauthier Industries is a Minnesota-based precision metal fabrication supplier serving top OEMs across multiple industries. Their capabilities range from simple stamped brackets to complex, fully assembled units, but their outdated CAM software was slowing them down. Without real-time rendering, accurate cycle time estimates, or advanced surfacing tools, the programming team struggled to iterate quickly, reverse engineer complex parts, and keep production moving.

Looking to eliminate those bottlenecks, Gauthier partnered with Midwest CAM Solutions to implement GibbsCAM. With real-time toolpath control, powerful surfacing and modeling features, and direct access to a responsive local support team, the difference was immediate. Programmers could now make multiple toolpath changes in real time, validate them instantly, and keep production flowing without interruption.

Beyond speed, GibbsCAM opened the door to capabilities the shop hadn’t had before. Reverse engineering became possible, new machining approaches could be tested on the fly, and complex parts that were once out of reach were suddenly within their capabilities. Combined with Midwest CAM’s hands-on support, the tool room is now faster, more flexible, and ready for whatever comes through the door.

A Shop Evolves

With services spanning machining, welding, powder coating, and assembly, Gauthier needed CAM software that could keep pace with their diverse and demanding workload.

Choosing Precision

GibbsCAM delivered the ability to make on-the-fly toolpath edits and validate changes instantly with no more long waits for reprocessing.

Dialed In

Midwest CAM Solutions provided not just software, but a partner who encouraged experimentation and innovation.

From Friction to Flow

Programming that once caused delays is now smooth and fast, empowering the team to meet tight deadlines and tackle complex work confidently.

Final Results

With GibbsCAM in place and support from Midwest CAM Solutions, Gauthier Industries has removed programming roadblocks, gained confidence in their toolpaths, and built a more responsive, flexible workflow that supports fast iteration and real-world production needs.