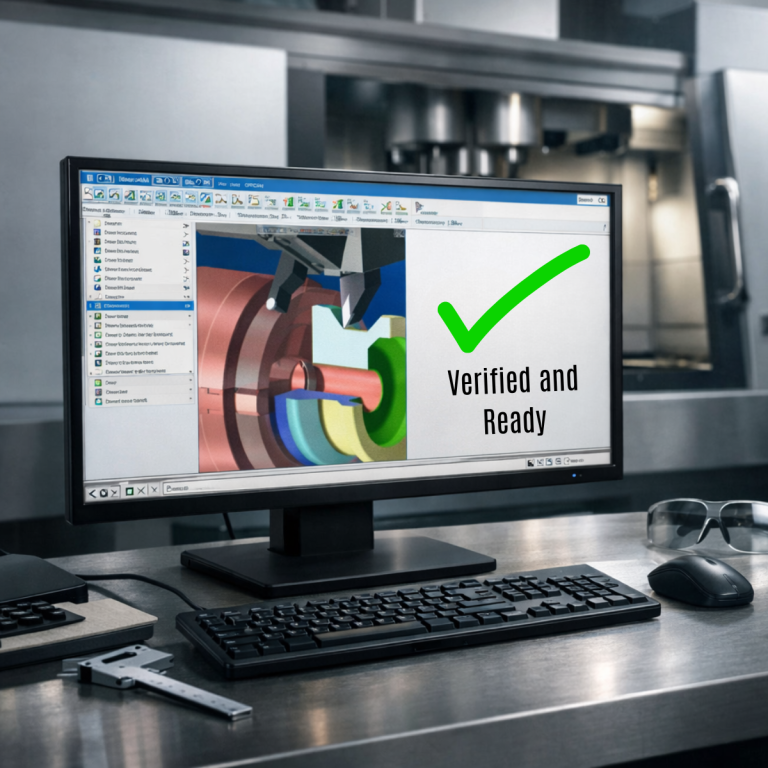

Free Resource for CNC Professionals

Before You Post Checklist

A simple checklist to help CNC programmers avoid costly mistakes, reduce scrap, and keep machines running safely and efficiently.

Stop Mistakes Before They Cost You

Reduce Costly Mistakes

Even the smallest programming error can have significant consequences. A few extra minutes of review can protect your profits, keep production on track, and save your team major headaches.

Improve Programming Confidence

Walk onto the shop floor knowing your program is ready to run with fewer surprises, smoother setups, and less stress.

Save Time and Keep Machines Cutting

A quick double-check upfront prevents hours of rework later, keeping your machines running efficiently and projects on schedule.

The Risk of Skipping a Double-Check

Every machinist has felt it — the rush to get a program on the machine and hit cycle start. But one missed offset, an unchecked coolant setting, or a wrong tool callout can turn that shortcut into hours of downtime, scrapped material, and frustrated operators. The pressure to move fast often costs more than the time you thought you saved.

That’s why we created the Before You Post Checklist. It walks you through the critical steps to review before sending any program to the floor. From toolpaths and setups to machine parameters and safety checks, this list ensures nothing slips through the cracks. Whether you’re programming simple parts or running complex multi-axis jobs, the checklist keeps your process sharp, your machines cutting, and your team focused on making chips, not fixing mistakes.

70% of shop downtime

Studies show that the majority of unexpected downtime comes from preventable programming or setup errors.

$100–$500 per scrapped part

Even one wrong offset or toolpath can waste hundreds of dollars in material and labor.

20–30 minutes lost per mistake

Every time a program crashes, needs rework, or forces a mid-cycle stop, you lose production time.

Built by Midwest CAM Solutions. Trusted Support & Proven Results

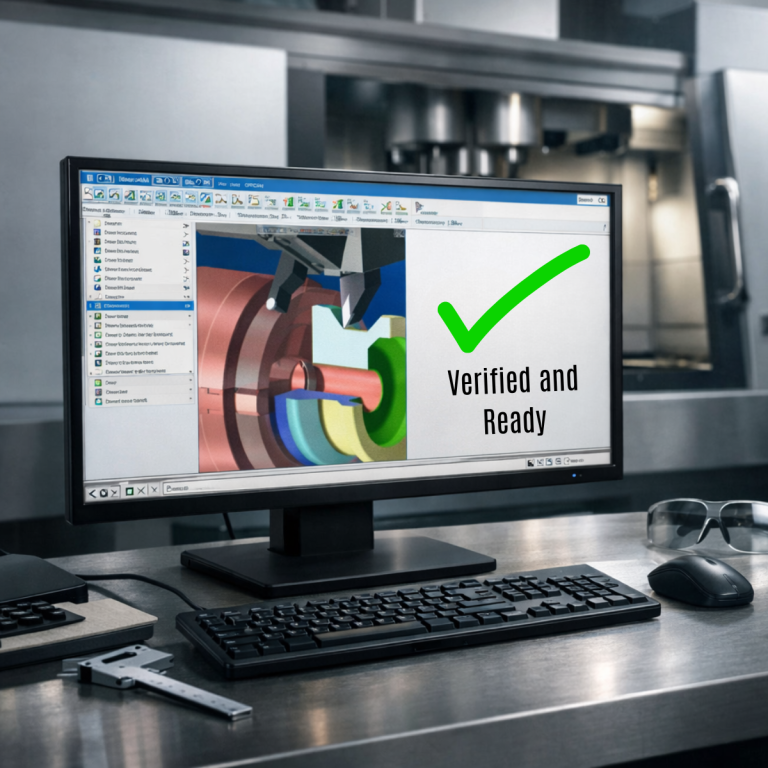

Free Resource for CNC Professionals

Before You Post Checklist

A simple checklist to help CNC programmers avoid costly mistakes, reduce scrap, and keep machines running safely and efficiently.