GibbsCAM 2026 | The Future of CAM

Built to automate the grind, sharpen precision, and put hours back in your day, because every minute your spindle turns, you win.

What’s New in GibbsCAM 2026?

The 2026 release brings smarter automation, sharper visualization, and real-world workflow upgrades that make programming faster, collaboration easier, and setup more predictable. Here’s a look at the biggest upgrades shaping the future of CAM:

visibility for the whole shop

GIBBSCAM VIEWER

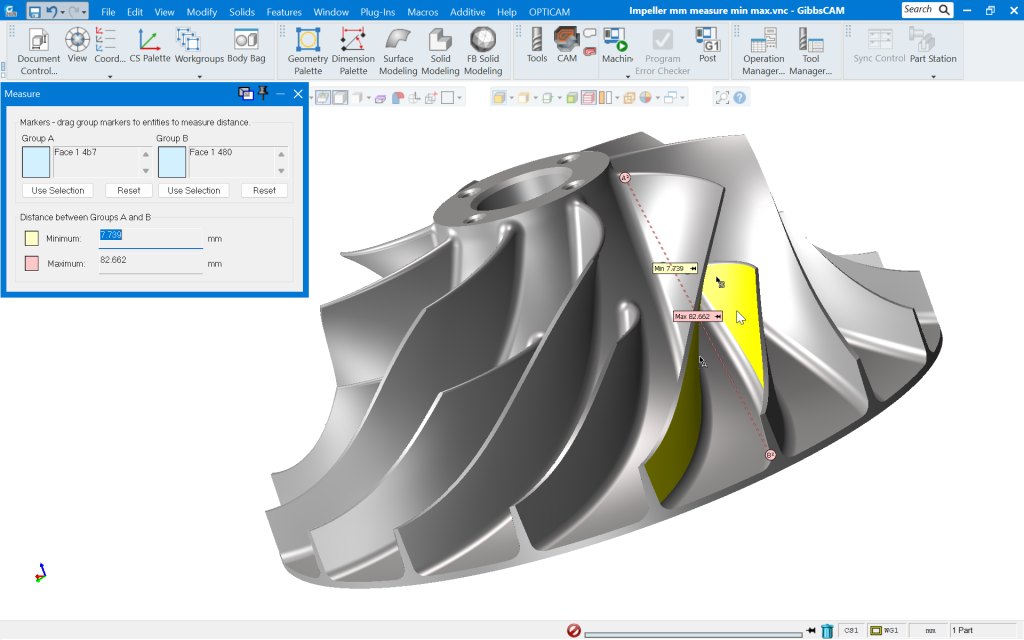

The new GibbsCAM Viewer brings programming visibility to every level of your organization. Operators, engineers, quality teams, and managers can all explore, measure, and verify parts with the same intuitive interface; no edits required, just clarity and confidence.

Open and inspect GibbsCAM files anywhere in your workflow to keep everyone aligned & informed.

Run realistic part simulations, check toolpaths, & confirm setups before a single cut is ever made.

Measure geometry, review dimensions, and generate reports to speed up inspection & handoff.

Feature Highlights

A closer look at the innovations shaping the Future of CAM.

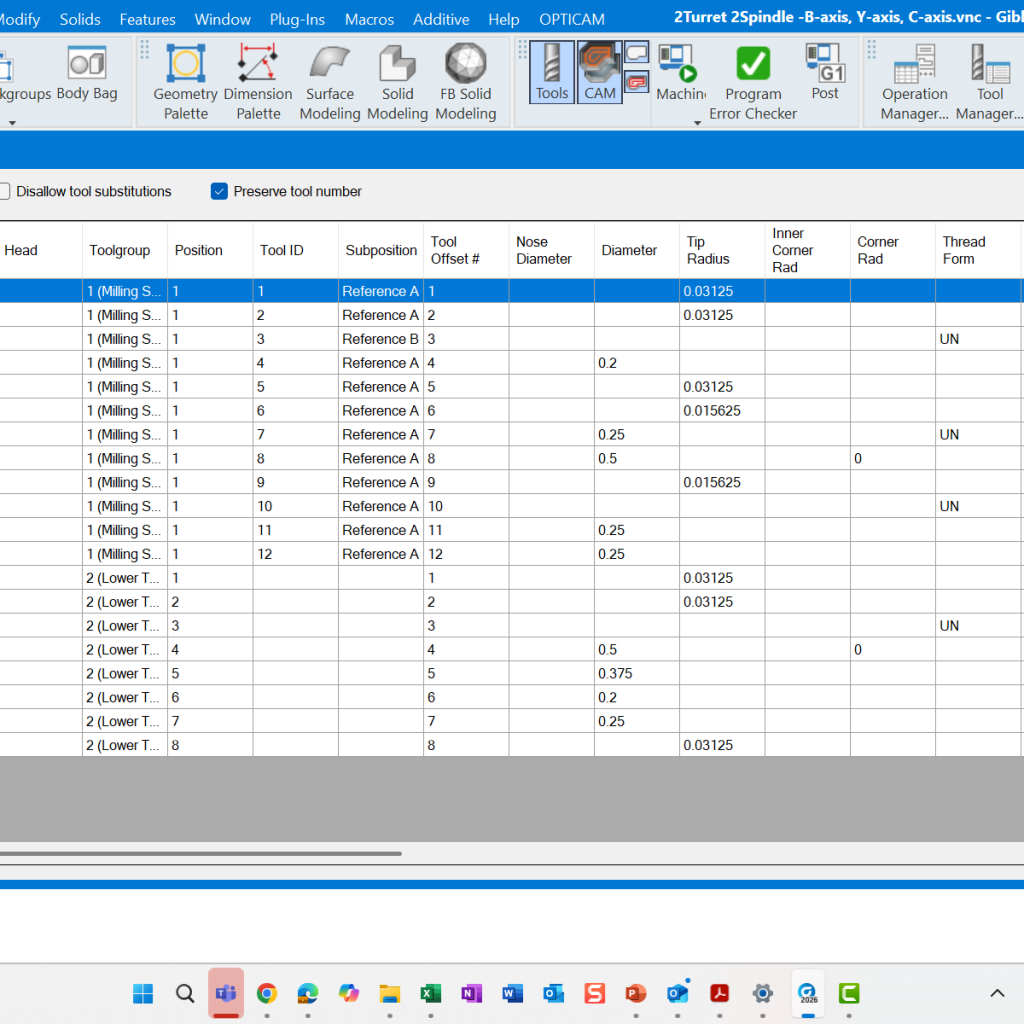

Tool Usage Reporter

The new Tool Usage Reporter gives you instant visibility into every operation tied to a specific tool, helping you manage complex projects with precision and clarity.

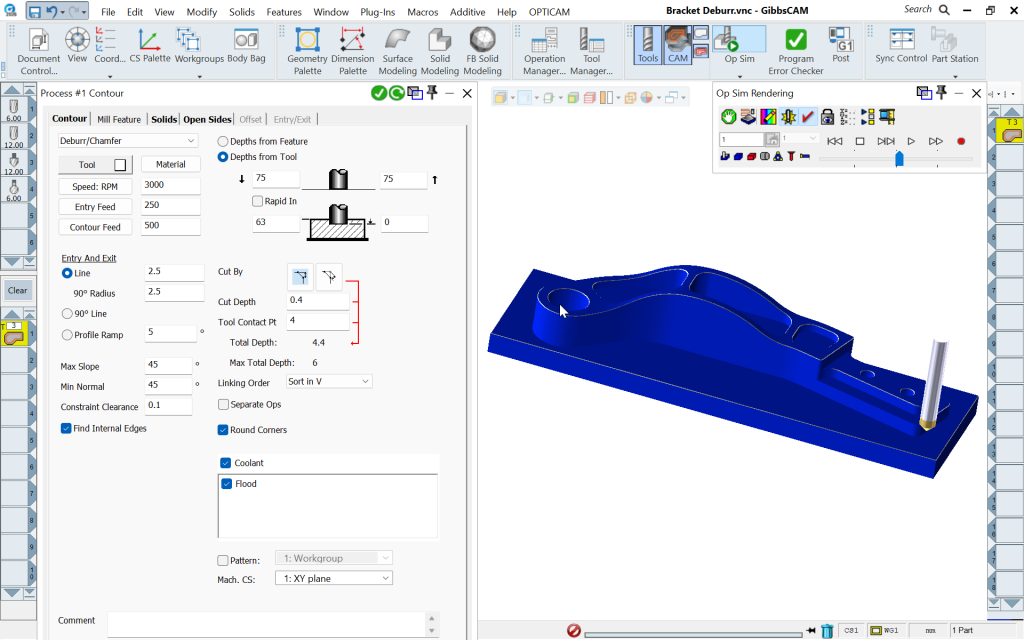

Automated Debur and Chamfer

Edge finishing is easier than ever with the new automated Debur and Chamfer functionality built directly into the Mill Contour process. Apply chamfers or deburring to part edges in just a few clicks (manually or automatically across your entire model) for clean, consistent results every time.

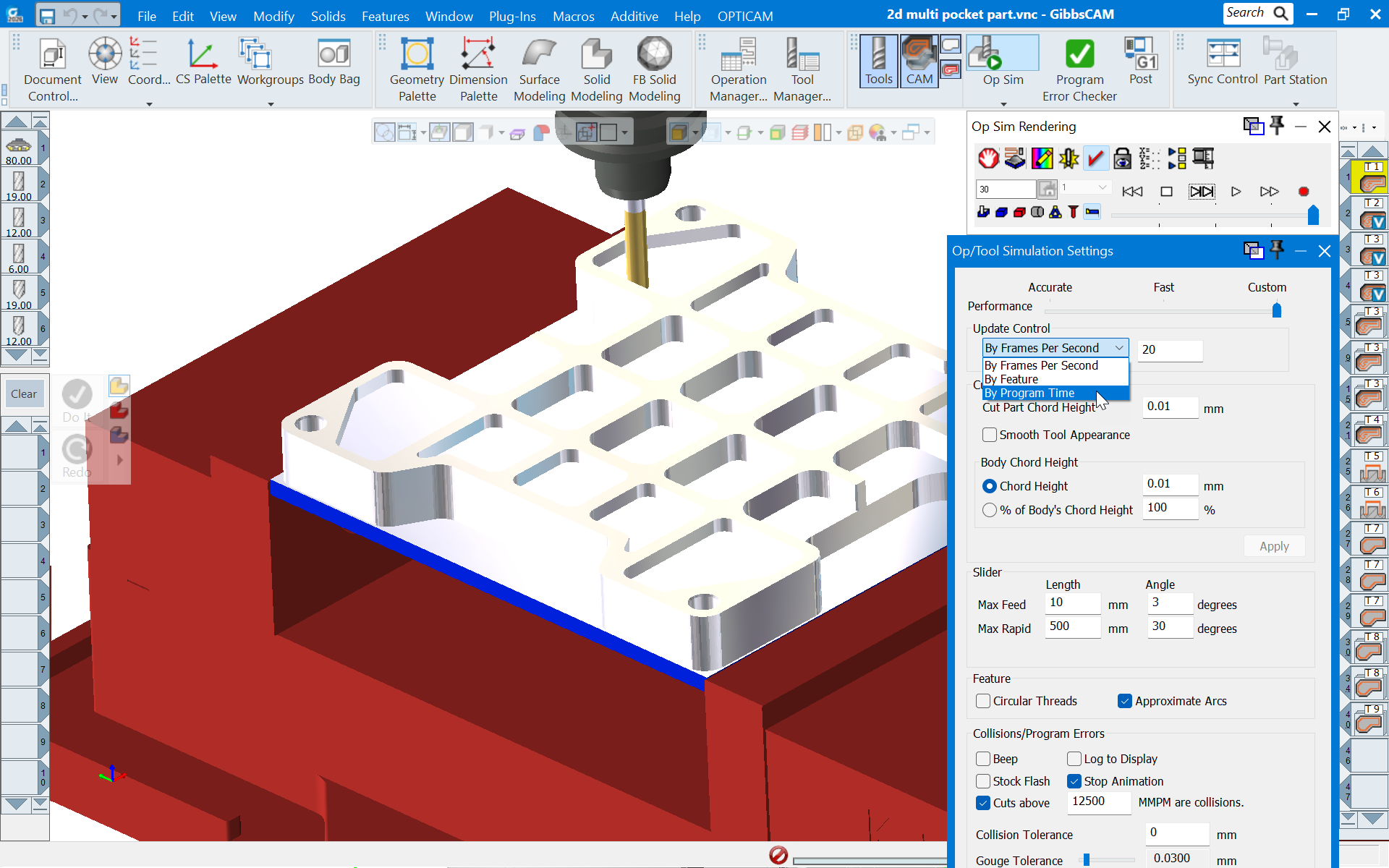

Metallic Rendering

GibbsCAM 2026 introduces new metallic rendering options that bring your simulations to life with realistic lighting and improved visual contrast. Apply metallic finishes to tools, fixtures, and highlights like Target, ActiveOp, and Clash to make complex setups easier to read and verify at a glance.

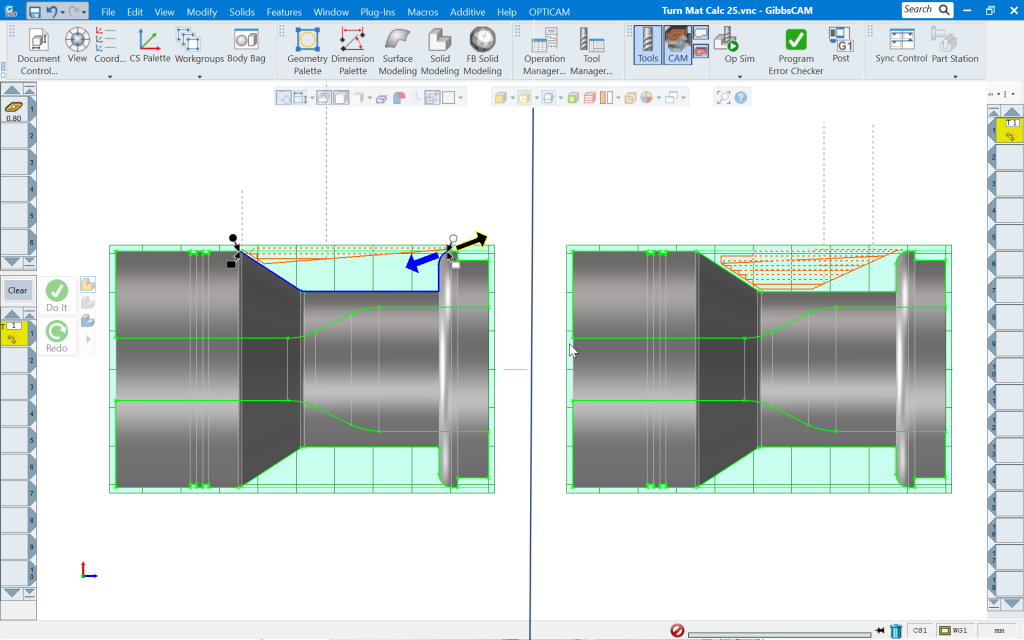

Multi-Sided Turning

Toolpath generation for multi-sided turning tools is now faster and more intelligent, automatically calculating material engagement to maximize insert geometry while maintaining safety and consistency. The result is smoother cuts, better chip control, and higher productivity in advanced turning operations.

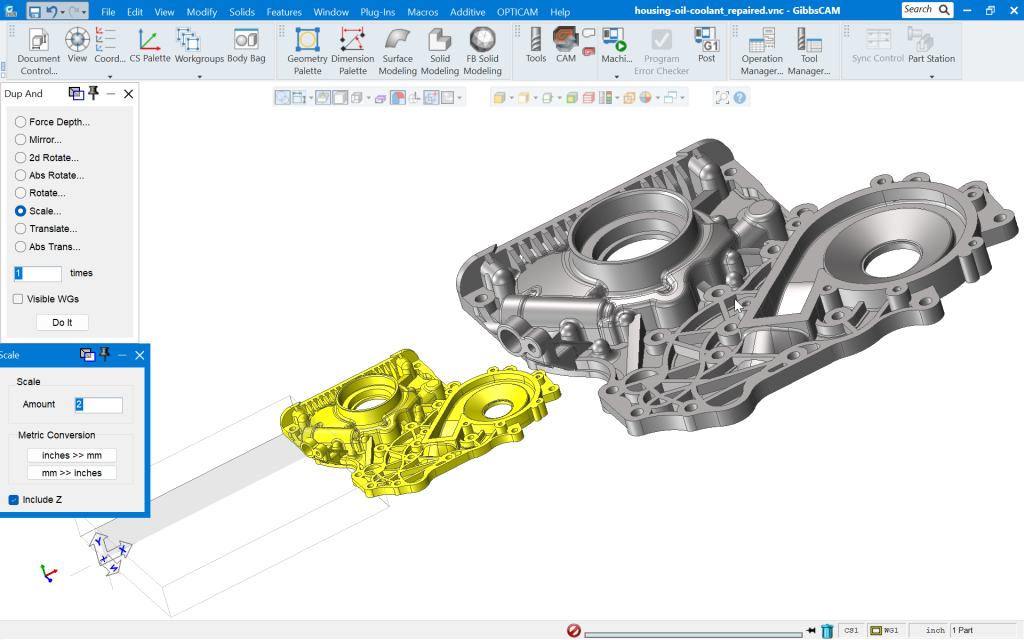

Scale and Rotate Tools

GibbsCAM 2026 expands its geometry tools to make scaling and rotation faster, easier, and more accurate. The enhanced Scale function now supports solid bodies, facet bodies, and sheets, allowing quick resizing while maintaining all part attributes.

Multiblade Machining Improvements

The latest multiblade enhancements deliver higher-quality surface finishes while reducing non-cutting time and protecting delicate edges. Expanded tool support and customizable feed controls give you more precision, flexibility, and speed across complex multi-axis operations.

See the Whole playlist

Explore the full GibbsCAM 2026 Feature Series to see all the latest tools, upgrades, and workflow improvements in motion. From AI Copilot to smarter simulation, each video walks through what’s new and how it makes programming faster, easier, and more precise.